Device for preventing low return water temperature to the boiler

92,89 €

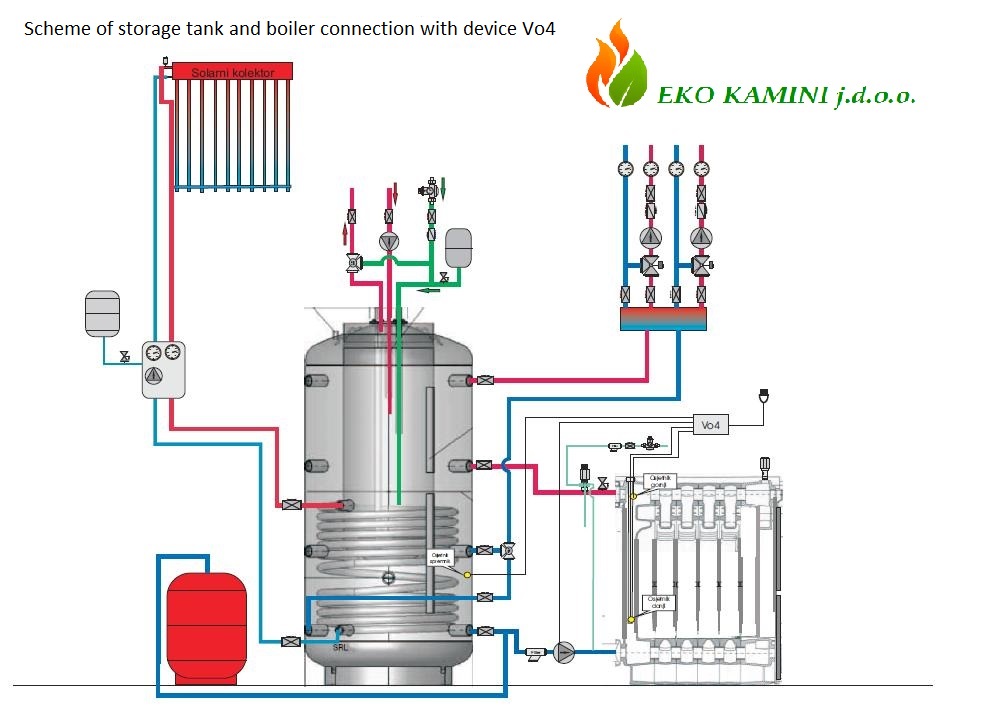

The main function of the VO-4 assembly for controlling a solid fuel boiler pump is to prevent condensation of the boiler during the transition periods of boiler heating and cooling.

VO-4 device for preventing low return water temperature to the boiler. VO-4 controls the solid fuel boiler pump (replacement with Ladomat).

By raising the return temperature above the dew point, we protect the boiler from low-temperature corrosion, and if we add a suitable heat accumulator (buffer) to the system, we will have superior heating comfort and ensure long-term and reliable boiler operation.

The main function of the VO-4 assembly for controlling a solid fuel boiler pump is to prevent condensation of the boiler during the transition periods of boiler heating and cooling. In addition, the circuit has a built-in function of protection against blockage of the pump, so that every 24 hours the pump is switched on at full power for five seconds.

Characteristics:

- temperature sensor in the upper zone of the boiler (flow)

- temperature sensor in the lower zone of the boiler (return)

- circulating pump modulation

- 230 V power supply

- prevents hydraulic shocks of cold water

- protects the boiler from low-temperature corrosion

- compact dimensions

IMPORTANT: The circuit can only operate the pumps without any electronics. The pump can have a speed control with a switch that selects the stator windings of the pump, in order to change the speed.

Working principle:

The protection of the boiler is achieved on the principle of gradual acceleration of the pump operation from the set minimum temperature in the boiler / return line (Tpoc) to the normal operating temperature (Tzavr). At Tpoc, the pump starts at minimum speed. In order for the pump to start safely, the pump receives the full supply voltage for one second every 20 seconds. The pump gradually accelerates as the boiler temperature rises according to a special algorithm. The pump reaches full operating power when the boiler temperature reaches the temperature Tzavr. At all boiler temperatures higher than Tzavr, the pump runs at full power. When cooling the boiler, the principle is the same, but in the opposite direction. The pump switches off when the boiler temperature drops below Tpoc. The Tpoc and Tzavr temperatures are set at the factory.

Mounting the VO-4:

The assembly is mounted on the wall with the supplied screws / dowels according to the enclosed template. No connection is required in the housing of the device. The assembly is connected to the heating pump with a 3×075 mm² connection cable (black – to connector L; blue – to connector N and yellow-green to the PE pump of the heating pump).

The sensor needs to be pushed into the boiler sleeve as deep as possible. The mains supply to the mains supply (230V / 50Hz) is connected by a mains cable with a socket. Immediately after switching on, the assembly is ready for operation and no further adjustment is required.

When the temperature at the lower sensor location reaches 40 ° C, the LED on the top of the case will start flashing. The flicker frequency corresponds to the speed of the pump and increases with increasing temperature.

At a temperature of 60 ° C the LED lights up permanently (the pump is running at full speed). The upper sensor will ignore the lower sensor only if the boiler temperature in the upper zone exceeds 85 ° C will turn on the pump and lower the temperature in the upper zone of the boiler for delta T 5 ° C.

IMPORTANT:

In order for the device to work properly, it is necessary to set the air regulator to a minimum temperature of 80 ° C, setting below the recommended temperature can cause incomplete combustion (burning without oxygen) and make maintenance difficult and damage cast iron boiler parts.

| Weight | 1 kg |

|---|

Only logged in customers who have purchased this product may leave a review.

Related products

Combined boiler for central heating Combitherm 45

Automatic for solar IR 12 CTC EN

| Name | IR 12 CTC 400-202 EN |

|---|---|

| Controlling | time compensation |

| Za solar | Yes |

| For heat pumps | Yes |

| For heating | Yes |

| Code | 15093 |

Boiler regulation TRS6 K

| Name | TRS6 K VČ. 5KS ČIDEL |

|---|---|

| Controling | time compensation |

| For solar | yes |

| For boilers and fireplaces | yes |

| For heating | yes |

| Code | 16821 |

Boiler regulation, automatic IR 12 FV1F CTC EN

| Name | IR 12 CTC EN FV1F COMPLET |

|---|---|

| Controlling | time compensated |

| For solar | Yes |

| For heating pump | Yes |

| For heating | Yes |

| Code | 17218 |

Solar regulation SRS1 T

| Name | SRS1 T VČ.2 KS ČIDEL |

|---|---|

| Controlling | diferentiating |

| For solar | Yes |

| Code | 17570 |

Solar regulation SRS2 TE

| Name | SRS2 TE |

|---|---|

| Controlling | diferentiating |

| For solar | Yes |

| Code | 14388 |

Solar regulation SRS3 E

| Name | SRS3 E |

|---|---|

| Controlling | diferenciating |

| For solar | Yes |

| Code | 13166 |

Reviews

There are no reviews yet.