Boiler with two fireboxes – Centrometal CentroPlus / CentroPlus-B

2.422,85 € – 3.406,33 €Price range: 2.422,85 € through 3.406,33 €

Boiler for central heating

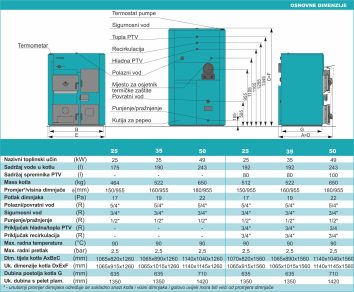

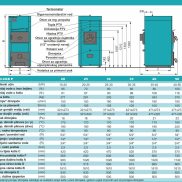

Thermal power: from 14 to 110kW

Fuel: wood, pellets, oil, gas

Centrometal CentroPlus and CentroPlus-B

- nominal heat output of 25-49 kW

- two separate furnaces in common boiler water

- the left firebox is used for heating with solid or liquid fuel

- the right firebox is used for heating with pellets or liquid fuel

The possibility of combining solid fuel heating and automatic switching on of the oil or pellet burner at the moment when the solid fuel does not meet the need for heat, makes this boiler especially interesting.

The successful combination of modern technologies and quality building materials with proven technical solutions give the boilers safety and reliability in operation with ease of installation and use. They are made in accordance with the European standard EN 304 and EN 303-5.

Basic characteristics of Centrometal CentroPlus and CentroPlus-B:

- Centrometal CentroPlus hot water boiler intended for central heating intended for heating using solid fuel, pellets and liquid fuel, rated heat output of 25, 35 and 49 kW

- Possibility of alternating use of both fireboxes

- Only one flue connection

- Possibility of installing thermal safety on factory-prepared openings

- A separate boiler body, separate formwork with thermal insulation and a separate oil or pellet set are supplied, which enables easy transport and installation and reduces the risk of damage.

- A special feature is the exceptional thermal and sound insulation

- A special feature is the exceptional thermal and sound insulation

- The boiler was tested and certified according to the European standard EN 303-5 and EN 304 at the Faculty of Mechanical Engineering and Naval Architecture in Zagreb and manufactured in accordance with the standard ISO 9001: 2008

Delivery content:

– boiler body with boiler door on a wooden pallet (with flap for the left hearth door, flap of the right hearth register, ashtrays, grate of the left and right firebox and turbulators);

– cardboard box with boiler casing, thermal insulation, thermometer, draft regulator (as CALEFFI 529 500 or ESBE C 20/25), rear ash box, cleaning accessories (accessory holder, brush, rake and poker), protective box for extension for pellet burner and set with screws and snaps

Solid fuel / liquid fuel firebox:

- Appropriately dimensioned combustion chamber and combustion of combustion gases in three passages ensure a high degree of boiler efficiency, which makes it “economical”

- The large door and the firebox of the boiler enable heating with large solid fuel and easy cleaning and maintenance

Liquid fuel / pellet furnace:

- Properly dimensioned firebox with turbulators ensures a high degree of efficiency of the boiler, which makes it “economical”

- The high water content in the boiler reduces the number of starts and prolongs the life of the burner and saves energy

- The boiler door is prepared for the installation of a pellet / oil burner

ADDITONAL EQUIPMENT:

Mandatory

- (solid fuel heating, without storage tank CAS) – manual 4-way mouse valve;

- (solid fuel heating, with storage tank CAS) – storage tank CAS, 3-way thermostatic valve;

- (closed heating system) – thermal valve (CentroPlus 25 / 35x1pcs, / 50x2pcs., CentroPlus-B 25/35 / 50x1pcs.), thermal exchanger (CentroPlus 50x2pcs.), safety vent group (2.5 bar) and expansion vessel;

- (open heating system) – open expansion vessel; for DHW code CentroPlus-B – safety valve (6 bar), expansion vessel, non-return valve.

| Weight | N/A |

|---|---|

| Snaga (kW) |

25 ,35 ,50 |

| Izvedba |

CentroPlus ,CentroPlus-B |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.