30-70% CHEAPER THAN METAL

FabricAir dispersion systems offer more money-saving options without sacrificing quality or design flexibility. Using FabricAir dispersion systems can result in savings of 30 to 70% over the cost of conventional channels. This is achieved through a simple installation process, economical transport solutions, space savings and efficient materials.

Adaptable system design

FabricAir dispersion systems have no restrictions when it comes to elbows, reducers and couplings, as is the case with conventional metal channels. If you can imagine that, FabricAir can produce. If you are used to a metal channel, then you know how to take your wallet when you hear “non-standard”. At FabricAir, what we do is non-standard, because every job is customized. Any angle, any length, any diameter… Call us and we will turn what you imagined into reality in three weeks or less.

The most dependable delivery dates in the whole industry

FabricAir has the fastest delivery time of any fabric channel manufacturer and delivers consistently on time. If you’ve ever had a project delayed because your equipment didn’t arrive on time, you know how important delivery on time is and how it can affect your deadlines. There are often liquidated damages included in construction contracts, and your buyer is not interested in why you could not complete the project on time. Don’t let the manufacturer be the reason. FabricAir will always deliver on time.

We are experienced professionals and use state of the art manufacturing technologies to ensure we have the best and most reliable delivery times in the industry.

Simple installation

FabricAir dispersion systems are intuitive and easy to install. Each section of the channel is marked with an individual tag that lets you know exactly where each piece should go. No tools needed to purchase; everything you need can be found in a plain toolbox. Easy installation significantly reduces operating time compared to metal ducts or other duct systems. This helps ensure you build your project on time and within budget.

Efficient soluntion for all room heights

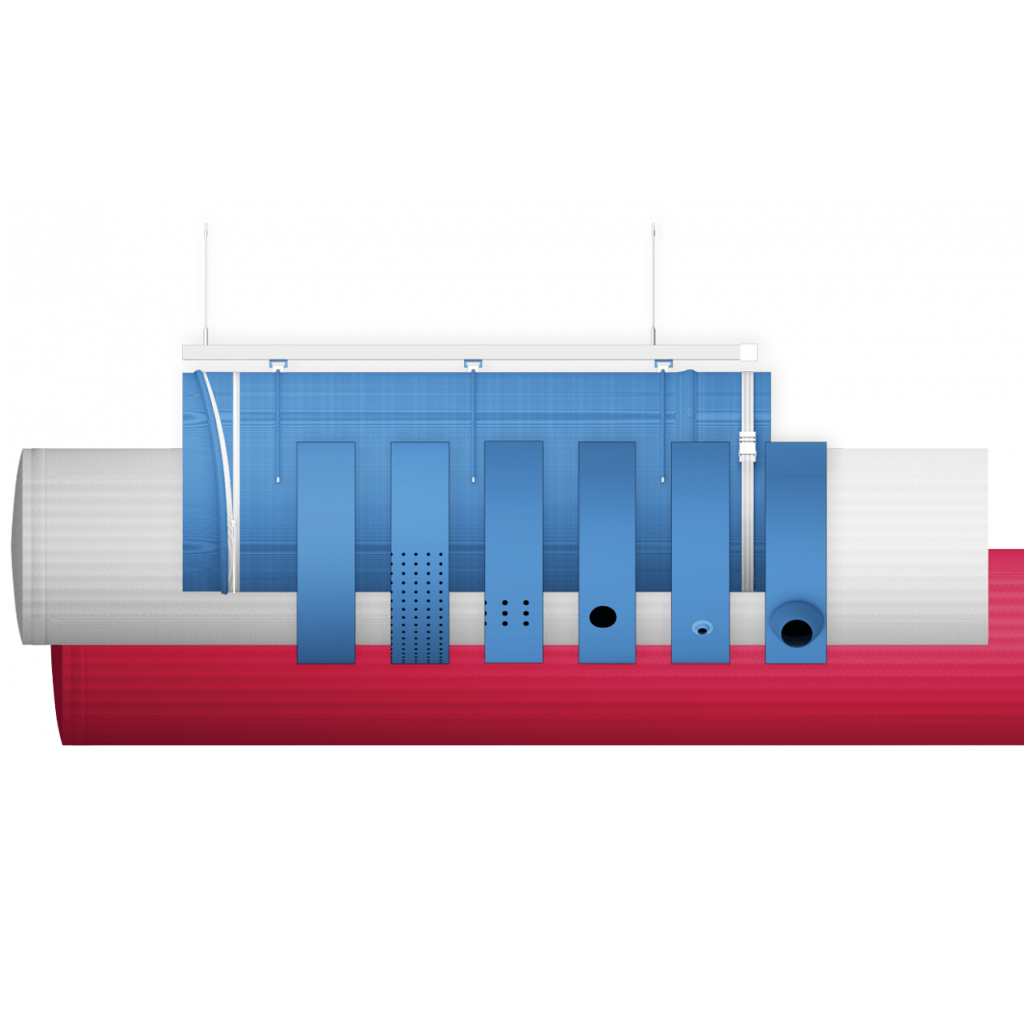

Depending on the application, FabricAir ducts and dispersion systems can be adapted to the specific needs of your building, using the best flow model or a combination of multiple flow models.

For example, in buildings with low ceiling heights, low-noise airflow models are often the choice to avoid drafts. However, if the building has high ceilings and requires heating, high emission flow models are used to ensure that the air reaches the occupied zone and helps to avoid stratification. FabricAir dispersion systems ensure ideal air distribution regardless of room size and ceiling height.

Everything is included into FabricAir dispersion system

Many of the functions known from conventional metal ducts are fully integrated into the FabricAir dispersion system, making diffusers, gratings, chokes, etc., redundant. FabricAir dispersion systems are comprehensive.

When using fabric air dispersion systems, you can forget about the following:

- No additional grilles or diffusers are required. FabricAir dispersion systems function both as a duct system and as an air dispersion system.

- No additional noise reduction is required (except perhaps a reduction in fan noise). Noise is standard.

- No inconvenient changes or installation on the construction site. The FabricAir dispersion system is customized directly from the factory, assembled with fasteners and ready for installation as soon as it arrives.

- No silencers. The FabricAir dispersion system does not require balancing.

- Dyeing is not necessary because the fabrics are dyed.

- No additional insulation. FabricAir dispersion systems are non-condensing.

A flow model to suit your specific needs

FabricAir manufactures many different flow models to meet the specific requirements of any project. The appropriate flow model depends on a number of specific project factors. What type of use is supplied: heating, cooling, ventilation or a combination of all three types? Are there specific airflow requirements? Do the requirements vary from room to room? There are more questions that can be asked, and the answers determine which flow model fits your application. Rest assured, whatever the requirements of your application, FabricAir has a flow model to suit your needs.

Hygienic alternative to metal

FabricAir ducts are 100% polyester, making them a hygienic choice for your air distribution. Polyester is a thin plastic thread that does not absorb water. This makes it impossible for bacteria to live “inside” the fibers and if any impurities accumulate on the surface of the canal, it can be easily washed away. If you have an application that is likely to cause harmful bacteria to the canal, such as food processing, you have the option to list one of our antimicrobial polyester canals. These unique qualities allow FabricAir dispersion systems to be preferred in slaughterhouses, laboratories, professional kitchens and any other place with strict hygiene requirements.

Light design for heavy channels

FabricAir offers the toughest working channels in the industry, in a lightweight design. Our channels weigh only 300 g / m2, so it’s like comparing a pen to a hammer, compared to conventional metal systems. This is especially important in connection with the subsequent installation of existing building mass, as FabricAir dispersion systems will not significantly affect the structural integrity. As a quick rule, using 3 kg / m for calculation purposes will provide a fair conservative estimate for structural engineers of 99% of all projects. The weight of the actual channel with suspension depends on the length and diameter of the channel. However, the most popular fabric, Combi, weighs 95% less than steel channels.

Longevity

FabricAir is the original channel manufacturer. We introduced the world’s first canal factory in 1973, so we have over 40 years of experience. Many of our initial installations are still fully functional and work the same as on the day they were installed.